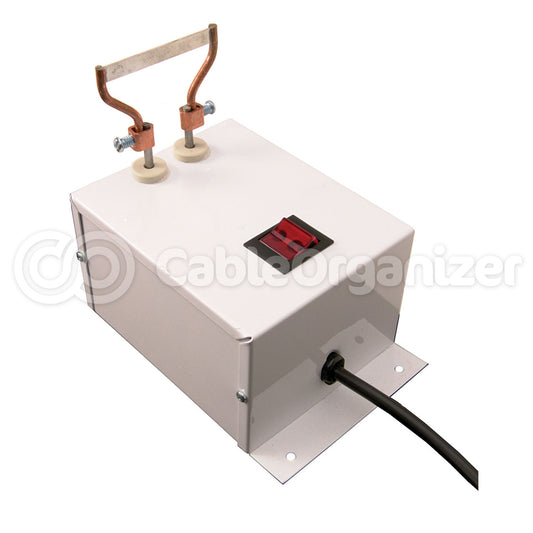

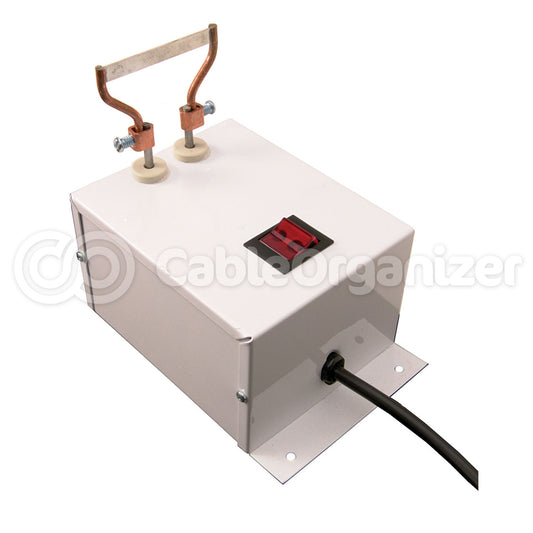

Heating, Installation, & Termination Tools

The CableOrganizer® Heating, Installation, and Termination Tools collection contains specialized gear to manage and finish cable projects with precision. Adhesive guns and glue guns can be used for assembly and sealing tasks. Heat guns help to apply heat shrink. Hot knives create flawless braided sleeving ends. Soldering torches are used for permanent electrical joins. And installation kits facilitate clean data and ethernet connections.

Heating, Installation, & Termination Tools

-

Best Sellers

Regular price From $9.99Regular priceUnit price / per

Regular price From $9.99Regular priceUnit price / per$9.99Sale price From $9.99 -

Regular price From $4.99Regular priceUnit price / per

Regular price From $4.99Regular priceUnit price / per$4.99Sale price From $4.99 -

Regular price From $66.37Regular priceUnit price / per

Regular price From $66.37Regular priceUnit price / per$66.37Sale price From $66.37 -

Regular price From $10.23Regular priceUnit price / per

Regular price From $10.23Regular priceUnit price / per$10.23Sale price From $10.23 -

Regular price $5.00Regular priceUnit price / per

Regular price $5.00Regular priceUnit price / per$5.00Sale price $5.00You can't add more product to the cart as we are sold out.

-

Regular price From $171.15Regular priceUnit price / per

Regular price From $171.15Regular priceUnit price / per$171.15Sale price From $171.15 -

Regular price $89.25Regular priceUnit price / per

Regular price $89.25Regular priceUnit price / per$89.25Sale price $89.25You can't add more product to the cart as we are sold out.

-

Regular price From $225.00Regular priceUnit price / per

Regular price From $225.00Regular priceUnit price / per$225.00Sale price From $225.00 -

Regular price From $296.52Regular priceUnit price / per

Regular price From $296.52Regular priceUnit price / per$296.52Sale price From $296.52 -

Regular price From $13.11Regular priceUnit price / per

Regular price From $13.11Regular priceUnit price / per$13.11Sale price From $13.11 -

Regular price $39.45Regular priceUnit price / per

Regular price $39.45Regular priceUnit price / per$39.45Sale price $39.45 -

Regular price From $11.23Regular priceUnit price / per

Regular price From $11.23Regular priceUnit price / per$11.23Sale price From $11.23